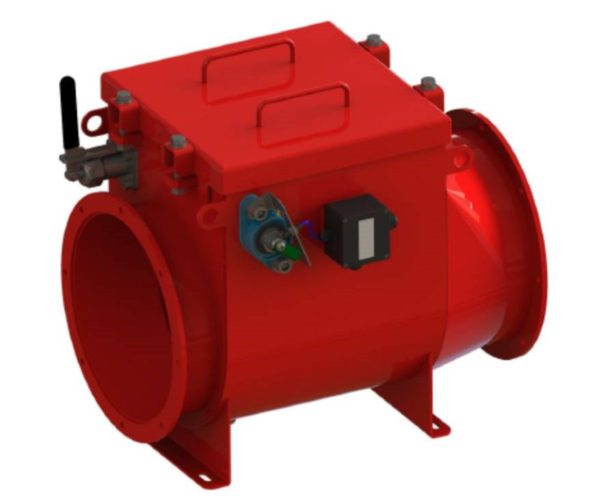

EXPLOSION ISOLATION VALVES

Home

The explosion isolation valve is used in order to prevent an explosion in the extraction filter being able to travel back through the ducting to the production premises or machines. The explosion isolation valve is mounted on the duct section between the extraction system and the source of the dust. The explosion isolation valve stops explosions that occur in the opposite direction of the normal flow. This means that the explosion isolation valve is mounted on the inlet side on the dust separator, never on the outlet side.

The explosion isolation valve is made of composite structural steel. Supplied with and without position switch. Furthermore, the valve is powder coated to corrosion class C3 cf. ISO 12944 (Colour: RAL 3000).

Tested and approved:

• Dust explosion class St. 1

• EN 16447 – Explosion insulation systems

• Quality assurance of protection systems in accordance with Directive

94/9/EF

The explosion isolation valves are manufactured in accordance with EN16447 Explosion insulation systems and Directive 94/9/EF

STANDARD SPECIFICATION

- DUST EXPLOSION CLASS St. 1

- COMPOSITE STRUCTURAL STEEL CONSTRUCTION

- POWDER COATED FINISH

- STANDARD COLOUR: RAL3000